Latest News

Innovative brewery collaborates with Plymouth College of Art team to capture and reuse CO2

Tuesday, 1 March, 2022 — As part of the Environmental Futures and Big Data Impact Lab project, Barnaby's Brewhouse are working with Plymouth College of Art and Fab Lab Plymouth on a system to reduce and reuse CO2 emissions from their beer production facilities.

<p dir="ltr"><a href="https://barnabysbrewhouse.com/" target="_blank" rel="noreferrer noopener">Barnaby’s Brewhouse</a>, a specialist Devon-based brewery which aims to create quality beers through sustainable business practices, has worked with <a href="http://plymouthart.ac.uk">Plymouth College of Art</a> and <a href="https://www.fablabplymouth.org/" target="_blank" rel="noreferrer noopener">Fab Lab Plymouth</a> to tackle carbon dioxide (CO2) emissions since 2019 as part of the <a href="https://www.impactlab.org.uk/" target="_blank" rel="noreferrer noopener">Environmental Futures and Big Data Impact Lab</a> (aka Impact Lab) project.</p>

<p dir="ltr">Barnaby’s Brewhouse, which is based on the Riverford Organic Dairy farm in Buckfastleigh, first approached Plymouth College of Art as part of its overall drive to use renewable energy sources and repurpose or reuse all waste products. The brewery’s work in this area recently made it to the finals of the COP26 'Heroes for Net Zero', for small UK businesses taking the most innovative action to go green and cut their own greenhouse gas emissions to become a net zero business by 2050.<br /></p>

From left to right: Ben Gale Tim Stacey and Ian Hankey in Fab Lab Plymouth

<p dir="ltr">The brewers are already certified organic by the Soil Association, using organic malt and hops sourced in the UK and propagating their own live yeast using organic malt extract, in addition to using water that comes from a natural spring rising on the organic farmland a few hundred yards from the brewery. In keeping with this ethos, Barnaby’s Brewhouse Directors Barnaby Harris and Tim Stacey are working with Plymouth College of Art to develop a system to reduce and reuse CO2 emissions from their beer production facilities.</p>

<p dir="ltr">Tim Stacey, Director of Barnaby’s Brewhouse and a process engineer by trade, said: “Most CO2 that’s available to buy for the hospitality industry is oil-based, created as a byproduct from fertiliser manufacturers. That goes against our environmental aims. I first approached Plymouth College of Art for help partly because I wanted to prove that being environmentally conscious is a good business decision. Capturing and reusing our carbon dioxide emissions makes good business sense. I’m confident that the work we’re doing together will pay for itself.”</p>

<p dir="ltr">As small-scale, independent brewers, Barnaby’s Brewhouse currently buys carbon dioxide from external suppliers to carbonate their beers, despite three times the volume of carbon dioxide that they needed already being produced as part of the fermentation process. This is because carbon capture systems, which are commonly used by large scale breweries, are currently prohibitively expensive to small and micro businesses.<br /></p>

<p dir="ltr">Barnaby’s Brewhouse came to Plymouth College of Art, specifically Knowledge Exchange Coordinator Ben Mundy and the other expert staff within Fab Lab Plymouth, for support in designing and prototyping a system to capture CO2 created through the fermentation process and filter out oxygen and odours so that it could be reused to carbonate the beers that they produce.</p>

<p dir="ltr">Ian Hankey, Principal Technician at Fab Lab Plymouth in Plymouth College of Art, became the lead researcher to work with Barnaby’s Brewhouse on the project. As a qualified gas engineer with over 40 years of experience in the glass industry and as the expert who established and formerly managed Fab Lab Plymouth, Ian was uniquely qualified to collaborate with Barnaby’s Brewhouse Director Tim Stacey, working from Tim’s concepts and plans to design and 3D print the components and sensors necessary to capture CO2 emissions and create a new system to purify the CO2 and monitor gas percentages. The collaboration between Tim and Ian was so committed to sustainability that when expensive parts were needed from overseas, the two would agree specifications and build them from more accessible materials, including using Plymouth College of Art’s hot glass facilities to blow tailored glass components.</p>

<p dir="ltr">The components are currently being trialled on site at Barnaby’s Brewhouse, with the goal of implementing the carbon capture and reuse system for full-time production. Once that process has been successfully implemented, Barnaby’s Brewhouse is seeking funding to turn the carbon capture system into a commercial package that can be offered to other small and micro-breweries and fermenters who cannot currently afford to capture and reuse their own carbon.</p>

<p dir="ltr">“In 2018 when we first started working with the Impact Lab,” Tim Stacey said, “it was clear that the UK has a problem in relying on CO2 that comes from fossil fuels. The national shortages in both 2018 and 2021 have reinforced the need to sequester and reuse our own CO2. Carbon dioxide prices doubled in the space of weeks, which puts everyone’s prices up. Without technology like the system that we’re developing, it will be much more difficult for microbreweries like ourselves to survive.”</p>

<p dir="ltr">Once fully implemented, the system will capture more carbon dioxide than is needed by Barnaby’s Brewhouse to manufacture and carbonate their drinks. It is now, therefore, looking at other innovative uses for the natural CO2. Recent research suggests that the correct use of CO2 in polytunnels can reduce pests and increase yields and the brewery is actively talking to a number of local growers about trialling this process.</p>

<p dir="ltr">“Ben Mundy at Fab Lab Plymouth has been instrumental in helping us to apply for further funding through the Impact Lab SME Grant Fund,” Tim Stacey said, “to take these ideas forward to the next stages.”</p>

<p dir="ltr">“From the outset, our goal has been to derive value from our waste products and pursue a circular economy approach. It’s a modern trend for companies to greenwash their activities and call themselves carbon neutral or even carbon positive, because they plant trees to ‘offset’ their environmental impact, but this doesn’t address the elephant in the room. Carbon offsetting doesn’t tackle the real problems created by business.”</p>

<p dir="ltr">“For Barnaby's Brewhouse, we want to follow evidence-research into how we can really make a difference. We’re looking at everything we can control within the walls of the business, from using locally-managed springwater to capturing and reusing our own CO2. As a philosophy, this makes us significantly more efficient, which in turn brings financial benefits. In the end, sustainability makes good business sense.”<br /></p>

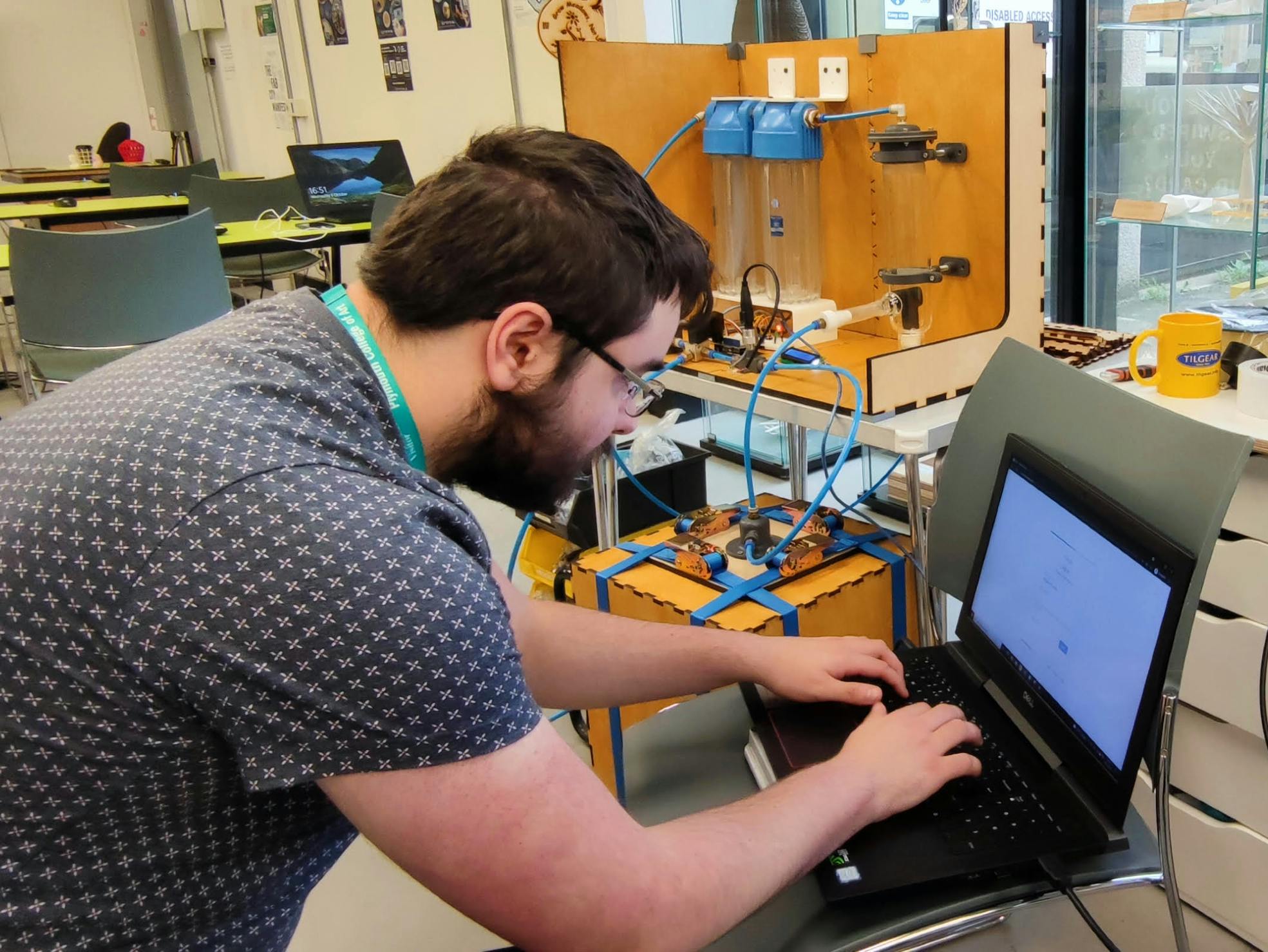

Ian Hankey in Fab Lab Plymouth

<p dir="ltr">The Impact Lab is a European Regional Development Funded project that harnesses the environmental and technical expertise of key Devon institutions as a resource for collaborative projects that help businesses in the county solve technical challenges in the development of a new product, service or process. The Impact Lab is a partnership comprising Plymouth College of Art, the University of Exeter, Exeter City Futures, the Met Office, University of Plymouth, Plymouth Marine Laboratory, and Rothamsted Research.</p>

<p dir="ltr">Tim Stacey said: “Having access to the level of skills that Ian Hankey and Ben Mundy have offered us would be almost impossible for a small business like ours, without having access to Fab Lab Plymouth and the Impact Lab. The machinery and equipment in Fab Lab Plymouth is invaluable, of course, but the fundamental technical training of the experts who work there are key to helping us translate our ideas into practical solutions. Through Fab Lab Plymouth, we’re tapping into a community, bringing together people from different businesses with different expertise to have conversations that wouldn’t have happened any other way. To scale up a small business like ours, we need automation, and the conversations, expertise and support offered through Fab Lab Plymouth are key to making that happen.”<br /></p>